Machinery

CNC Mill & Lathe

CNC Bed Mill with a work volume of 760mm in X axis, 380mm in Y axis and 560mm in the Z axis. Controlled via gcode, conversational input and manual DRO hand wheels. 3500 RPM with ISO30 tool holders, extremely capable for prototyping and production in all materials metal and plastic. Lots of tooling available too, end mills drills and more!

CNC Lathe coming very soon, controlled via gcode, conversational input and manual DRO hand wheels. Lots of tooling OD turning, ID turning, groveing, finishing and thread turning!

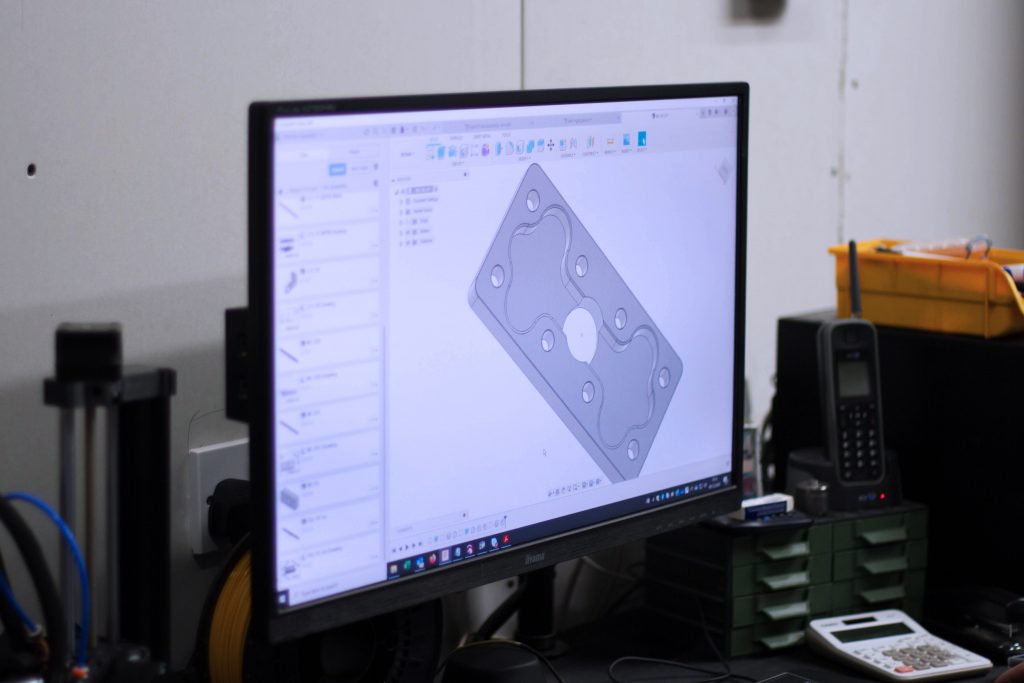

CAD/CAM Workstation

Our CAD/CAM Workstation is fully equipped and hassle-free, offering a Fusion 360 license right at your fingertips. You won't need to worry about licensing on the workstation. Complete with a spacious 32” wide monitor, an i7 processor, powerful NVIDIA Quadro P1000 graphics, and a robust 32GB of RAM, this powerhouse workstation is designed to make programming parts a breeze. It also comes equipped with a 3D space mouse, allowing you to rotate your models with ease for a more immersive and intuitive design experience. With its impressive specifications and seamless network connectivity, you'll experience lightning-fast transmission of tool paths to our CNC machines. Within seconds, your projects will be set in motion, allowing you to simply hit the 'cycle start' button and witness your designs come to life with unmatched efficiency and precision.

Horizontal/Vertical Band Saws

We offer a pair of user-friendly vertical and horizontal saws designed to simplify the process of cutting metals and plastics, getting them ready for processing in the lathe or mill, or for resizing stock materials. These saws come equipped with precise end stops, ensuring accurate and repeatable cuts for both plastics and metals. Whether you're working on intricate machining tasks or simply need to cut materials to size, our saws are reliable tools that enhance efficiency and precision in your projects.

Vibratory Tumbler/Polisher

Our compact vibratory tumbler is ideal for processing small parts, typically up to around 100mm square. While you may be able to accommodate larger parts, caution is advised to prevent parts from colliding. We offer three types of media for both dry and wet processing: resin beads for deburring, ceramic beads for polishing metals, and walnut shells for a finishing touch and brilliant polish. Additionally, our tumbler features variable speed control, allowing you to finely control the process for the best possible outcomes.

Bead Blast Cabinet

The bead blaster is primarily designed to provide a high-quality finish to parts rather than for removing dirt and rust. We offer a selection of glass round beads tailored for processing aluminum and steel components. When used with aluminium, these beads impart a matte finish, creating a porous surface while effectively removing machining marks. On steel parts, the beads work to polish the surface, achieving a smooth finish. It's important to note that bead blasting involves a rapid stream of media impacting your components, so caution is advised to avoid potential damage to delicate parts. For those seeking an even rougher finish, we provide a supply of smashed glass media. Additionally, we offer walnut shell media, ideal for polishing more intricate parts that may not be suitable for tumbling processes.

Tapping Arm and Surface Plate

Tapping parts can often be the crucial finishing touch to a project, so precision is key. We offer a range of quick-change collets from M3 up to M10, all securely mounted on a sturdy steel surface plate. These collets are powered by air, giving you precise control over the flow and pressure, enabling you to tap both small and large parts with the right torque. To make the process even smoother, our tapping station features an articulated arm, reducing the effort required. For your convenience, we provide tapping oil to ensure optimal results. Place your part securely in a vice and start tapping with confidence.

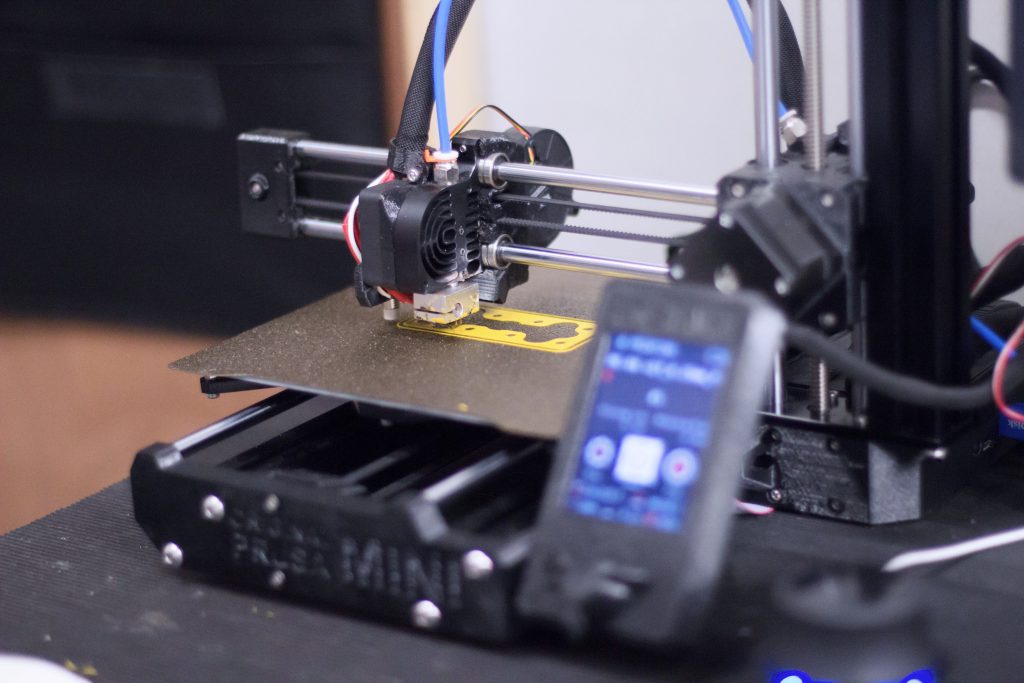

3D Printer (FDM and Resin)

We are equipped with two dependable Prusa MINI+ FDM printers, complemented by a selection of PLA filaments. These printers offer a generous work envelope of 180mm square, accommodating a variety of projects. Transferring files to these printers is a breeze, thanks to the software loaded onto our workstation. Please remember that the required file format for the software is a 3D .STL file. In addition to our FDM printers, we also have a resin printer dedicated to creating ultra-fine, intricate 3D objects. To ensure impeccable results, we provide a solvent wash and cure station for post-processing. What's more, you can have both FDM printers working simultaneously, providing you with faster results because, as they say, 'two's better than one!

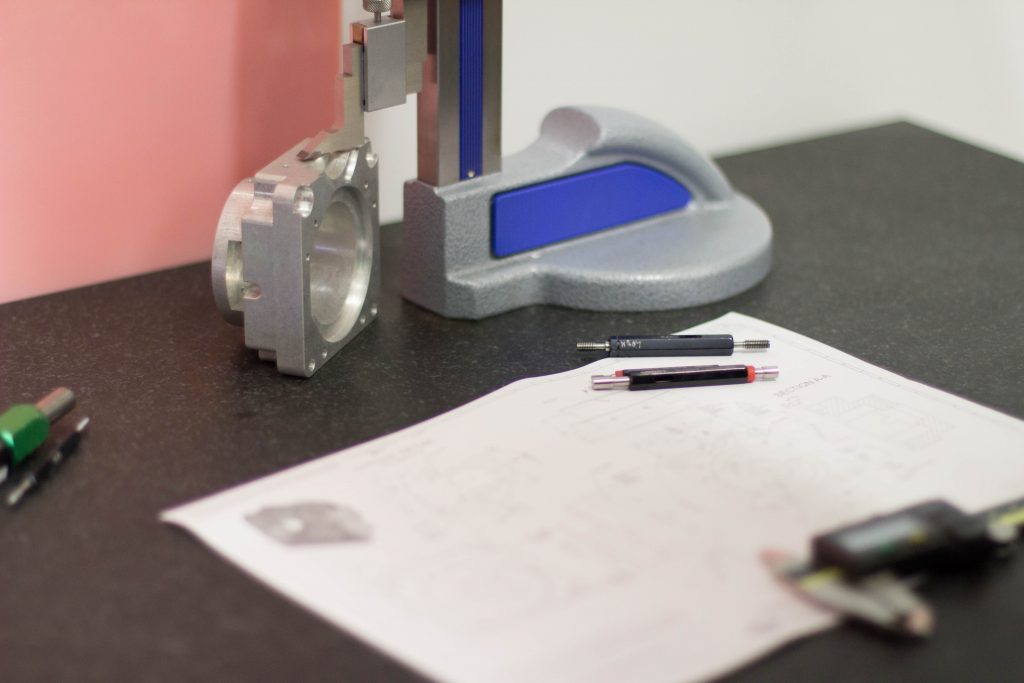

Inspection Tools and Granite Surface

So, you've successfully crafted your part. Now, it's time to ensure precision and accuracy in your measurements. Our workshop is equipped with the tools you need, including a Mitutoyo digital height gauge capable of measuring up to 450mm in height, Vernier calipers with a reach of up to 150mm, and a micrometre with precision down to .005mm. With these high-quality Mitutoyo measuring instruments and our granite surface, you can confidently verify the exact dimensions of your creation to meet your specifications.

Asembly Benches

We provide simple and sturdy workbenches equipped with a vice and tool setter, offering a combined work area of 1200mm square. These benches feature wooden tops and a durable steel frame, perfectly suited for our workshop environment. They provide an ideal surface for assembling and setting up your projects, ensuring a secure and reliable workspace for your tasks.

Book Now

Ready to transform your ideas into reality? Reserve your workshop space now.